(H1) FIBC Bulk Bags: The Powerhouse of Modern Bulk Packaging

In an era where efficiency, cost reduction, and safety are paramount, the logistics and manufacturing industries rely on a workhorse solution: the FIBC Bulk Bag. Also known as jumbo bags,吨袋 (dūn dài), or simply bulk bags, these versatile giants have revolutionized how dry, flowable products are stored, handled, and shipped across the globe.

But what makes them the preferred choice over traditional rigid containers like drums or boxes? Let's dive into the world of FIBCs and explore how they can transform your operations.

(H2) What is an FIBC (Flexible Intermediate Bulk Container)?

An FIBC is a large, flexible industrial container designed for storing and transporting dry, flowable materials—such as sand, fertilizer, plastic granules, and food ingredients—in large quantities. Typically holding between 500 to 2,000 kg, they are constructed from woven polypropylene, a material known for its high strength, durability, and cost-effectiveness.

Their design includes lifting loops that allow them to be easily moved by cranes or forklifts, making them incredibly efficient for bulk handling.

(H2) Key Advantages of Using FIBC Bulk Bags

The shift towards FIBCs is driven by a compelling list of benefits:

Significant Cost Reduction: FIBCs offer one of the lowest packaging costs per unit of weight. They are lightweight when empty, drastically reducing shipping and storage costs compared to metal drums or wooden crates. They can also be folded flat when not in use, saving up to 90% on storage space.

Unmatched Handling Efficiency: Designed for integration with modern material handling equipment, FIBCs can be filled, lifted, moved, and emptied quickly and safely. This streamlines the entire supply chain, reduces labor costs, and minimizes manual handling risks.

Superior Strength and Safety: Woven polypropylene is incredibly strong and resistant to tearing. FIBCs are rigorously tested for safe working load (SWL) and safety factor (typically 5:1 or 6:1), ensuring they can handle much more weight than their rated capacity.

Customizable Protection: Not all products are the same. FIBCs can be customized with various liners and coatings to protect contents from moisture, static electricity, contamination, and UV exposure.

Environmental Sustainability: FIBCs are reusable and recyclable. Their ability to be used multiple times for many applications and their high recyclability rate make them a more eco-friendly choice than single-use alternatives, reducing overall packaging waste.

(H2) Choosing the Right Type of FIBC for Your Needs

Selecting the correct FIBC is critical for safety and performance. The main types are defined by their static safety properties:

Type A FIBC: Made from standard polypropylene without any static protection. Only for non-flammable products and environments.

Type B FIBC: Made from a low-breakdown-voltage material that prevents propagating brush discharges. Ideal for products with minimal flammability but not for environments with combustible dust or flammable gases.

Type C FIBC (Conductive): Constructed with interwoven conductive threads that are grounded during filling and discharging. This safely dissipates static charges. Essential for flammable solvents, powders, or environments with a high risk of explosion.

Type D FIBC (Static Dissipative): Uses special fabrics or filaments to safely dissipate static electricity without the need for grounding. This offers superior safety and convenience in potentially explosive atmospheres.

(H2) Industry Applications: Where Are FIBCs Used?

The versatility of bulk bags makes them indispensable across a wide range of sectors:

Chemicals & Plastics: Transporting plastic resins, pigments, fertilizers, and industrial compounds.

Food & Agriculture: Handling flour, sugar, grains, seeds, and other food-grade ingredients (using FDA-compliant bags).

Pharmaceuticals: Storing and moving raw materials and powders in a controlled, contaminant-free manner.

Construction: Moving sand, cement, gravel, and other aggregates efficiently to and around job sites.

Mining & Minerals: Packing ores, minerals, and clays for large-scale transport.

(H2) A Smart Investment for a Streamlined Supply Chain

Integrating FIBC bulk bags into your operation is more than just a packaging decision—it's a strategic logistics decision. They represent a smarter, safer, and more economical way to manage your bulk materials from production to end-user.

(H1) Find Your Perfect Bulk Packaging Solution

Choosing the right FIBC partner is crucial. You need a supplier who understands safety standards, offers expert guidance, and provides reliable, high-quality products.

Ready to optimize your bulk handling, reduce costs, and enhance safety? Explore our comprehensive range of certified and customizable FIBC solutions tailored to your specific industry needs.

|

Description

|

FIBC/Jumbo bag/bulk bag/ pp big bag/Flexible container bag professional manufacturer

|

|

Type of bag

|

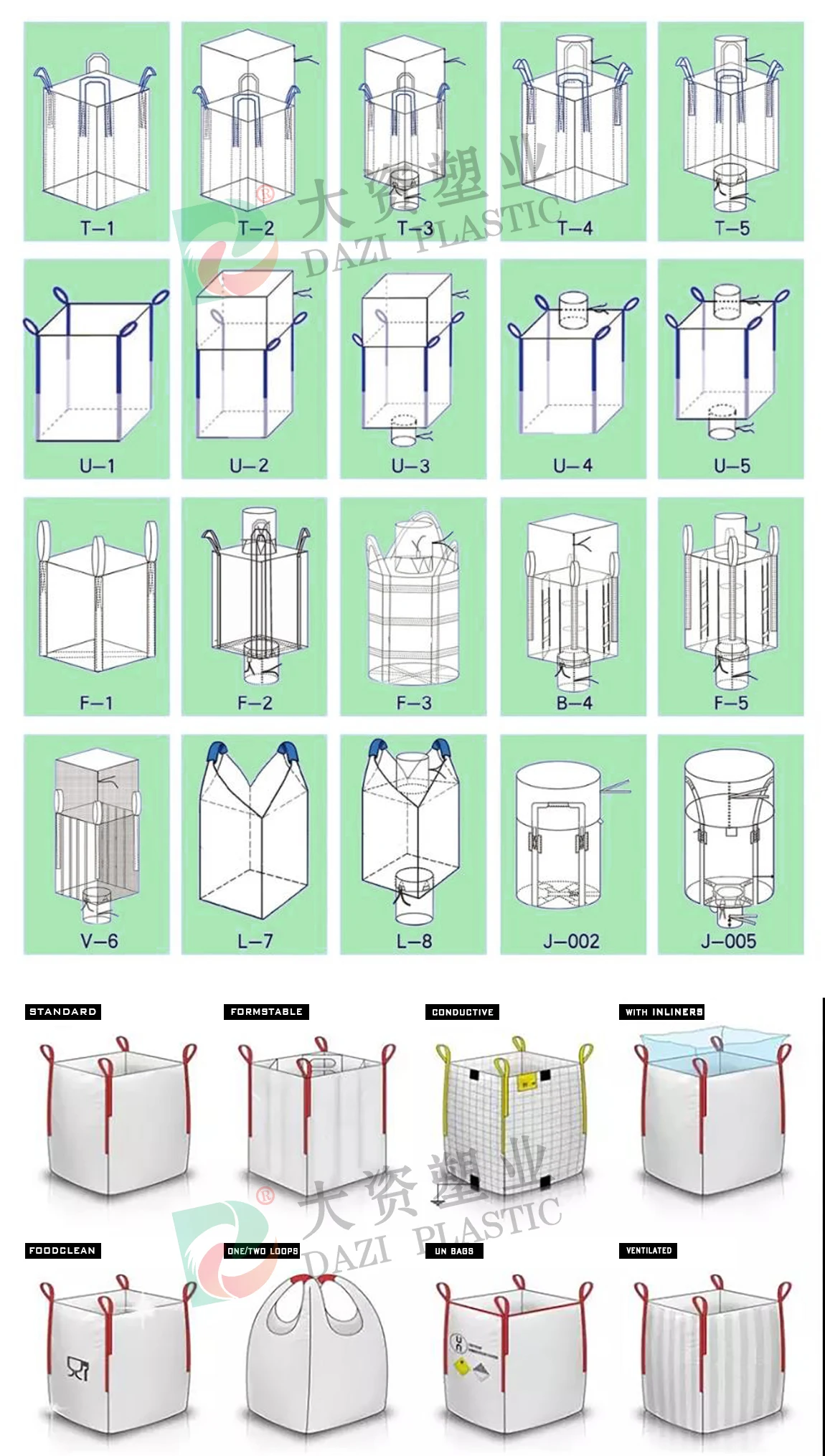

Tubular/Circular/U-panel shape//Rectangular

|

|

Material

|

100% Virgin PP

|

|

Fabric

|

Laminated/Plain/Vent/Conductive

|

|

Size

|

Customized

|

|

GSM

|

110gsm-230gsm

|

|

Color

|

Customized

|

|

Printing

|

Customized

|

|

Top

|

Full open/Filling spout/Top skirt/Duffle

|

|

Bottom

|

Flat/plain/with discharge spout

|

|

Liner

|

Liner(HDPE, LDPE) or Customized

|

|

Lifting loop

|

Cross-corner loops/4 Point 2 Strap lifting loop/Double Stevedore Strap/with belt/Fully belt loop/Loop in loop

|

|

Sewing

|

Plain/chain/chain lock with optional soft-proof

|

|

Ropes

|

1 or 2 around the bag body/customized

|

|

SWL

|

500-2000KG

|

|

SF

|

5:1/6:1/or as customer's requirement

|

|

Treatment

|

UV treated or not UV treated

|

|

Surface Dealing

|

Coated or plain,printing or no printing

|

|

Usage

|

Storage and packing

Mine,ore,fertilizer,chemical,onion,potato,grain,wheat,maize,rice,peanut,sugar,salt,agriculture,building material,powder,cement,etc. |

|

Processing

|

Yarn drawing-Circular weaving/Webbing-Quality inspection-Coating-Film

blowing-Cutting-Printing-Sewing-Checkout-Packaging-Transportation |

|

Delivery time

|

15-30 days

|

|

Certification

|

ISO22000, ISO9001, ISO14001, LABORDATA, etc.

|

|

Remark

|

Please let us know your specific requirements

|