Meta Description: Think FIBCs are just simple bags? Think again. Discover how advanced designs in bulk bags are driving efficiency, enhancing safety, and creating new opportunities for branding and sustainability.

URL Slug: smart-fibc-design-supply-chain-value

(H1) Your Bulk Bag is Smarter Than You Think: It's a Strategic Asset

Most businesses view the FIBC bulk bag as a simple container—a necessary, but passive, part of the supply chain. It gets filled, it gets shipped, it gets discarded. But this perspective is outdated. Today's advanced FIBCs are dynamic, intelligent assets engineered to solve complex logistical challenges, mitigate risks, and even amplify your brand message.

It's time to look beyond the woven polypropylene and see the strategic value within. How can a "simple bag" be so powerful? Let's explore.

(H2) The Evolution: From Container to Integrated Solution

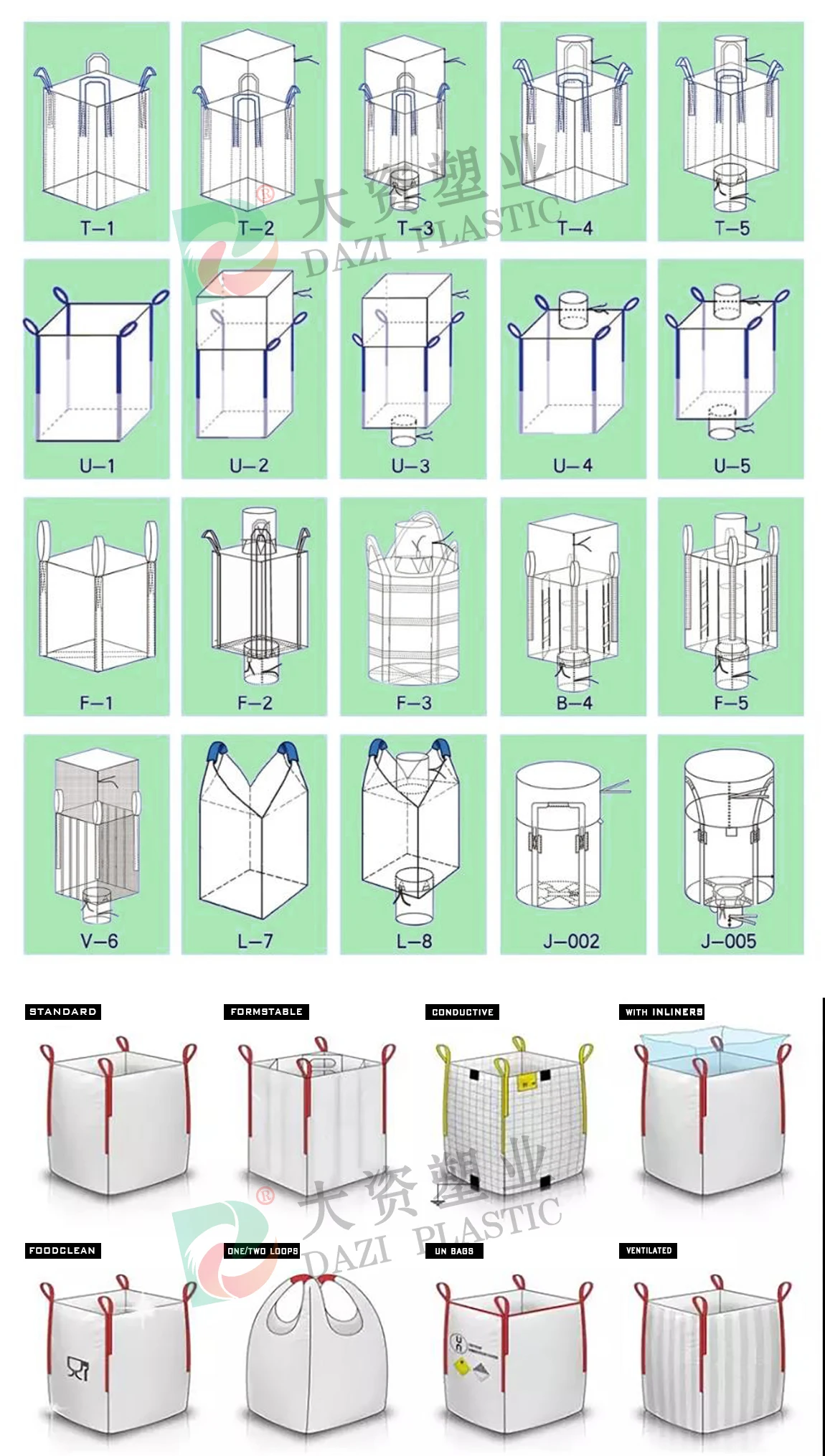

The modern FIBC is no longer a commodity. It's a custom-engineered solution. The key lies in its design versatility, which can be tailored to create significant competitive advantages:

The Safety Engineer: For industries handling combustible powders or operating in hazardous environments, the choice of FIBC is a critical safety decision. Type D Static Dissipative bags, which prevent explosions without requiring grounding, are not just a product—they are an integral part of your facility's safety protocol, reducing liability and protecting your workforce.

The Barrier Guardian: Product degradation costs millions. Advanced FIBCs with multi-layer laminate liners act as sophisticated barriers. They don't just keep moisture out; they can be specified to control oxygen ingress for sensitive food products or contain potent odors for chemical compounds, ensuring product integrity from factory to customer.

The Logistics Optimizer: Design features directly impact handling speed and cost. Circular bags offer better stability and stackability, maximizing warehouse space. Baffles prevent bulging, creating a uniform, space-efficient cube for shipping. Specific discharge options (like spouts or duffle tops) can be engineered to integrate directly with your customer's production line, reducing dust and streamlining their process.

(H2) The Unseen ROI: Calculating the True Value of a Smart FIBC

When you calculate the cost of an FIBC, look beyond the unit price. Consider the "Cost-in-Use":

Reduced Loss & Damage: A superior barrier liner prevents tons of product from being spoiled by moisture or contamination. This saving alone can justify the investment in a higher-specification bag.

Labor & Time Efficiency: Bags designed for easy filling and fast, clean emptying reduce the man-hours required for handling. A smooth discharge spout can empty a bag in minutes versus struggling with a standard design for much longer.

Waste Disposal Costs: The shift towards reusable FIBCs creates a circular economy model. By implementing a take-back and reconditioning program, companies can drastically cut their per-trip packaging cost and minimize their environmental footprint, a key metric for modern ESG (Environmental, Social, and Governance) reports.

(H2) Your Mobile Billboard: The FIBC as a Brand Ambassador

In a B2B world, your packaging travels through multiple touchpoints—shipping yards, warehouses, and factory floors. A standard, unprinted bag is a missed marketing opportunity.

A professionally custom-printed FIBC transforms a generic container into a powerful brand asset. Your logo, company colors, and handling instructions are displayed on a massive, mobile canvas. This reinforces brand recognition at every stage of the supply chain, projecting an image of quality and professionalism to everyone who sees it.

(H2) The Future is Connected: The Rise of "Smart" FIBCs

The next frontier is already here. Imagine an FIBC equipped with a simple, inexpensive QR code or RFID tag. When scanned, this could provide:

Batch and Lot Tracking: Instant access to manufacturing data and quality certificates.

Supply Chain Visibility: Real-time location and status updates.

Usage Instructions: Direct links to safety data sheets (SDS) or handling videos.

This level of data integration turns the FIBC from a dumb container into a key node in your IoT (Internet of Things) strategy.

(H1) Rethink Your Bulk Packaging, Unlock Your Potential

The question is no longer "Where can we buy bulk bags?" but "How can our bulk packaging strategy work harder for our business?" Partnering with an FIBC supplier that understands this shift—one that offers design expertise, not just products—is crucial.

Ready to transform your FIBCs from a cost center into a strategic advantage? Let's collaborate to engineer a bulk packaging solution that drives efficiency, safety, and growth for your business.

|

Description

|

FIBC/Jumbo bag/bulk bag/ pp big bag/Flexible container bag professional manufacturer

|

|

Type of bag

|

Tubular/Circular/U-panel shape//Rectangular

|

|

Material

|

100% Virgin PP

|

|

Fabric

|

Laminated/Plain/Vent/Conductive

|

|

Size

|

Customized

|

|

GSM

|

110gsm-230gsm

|

|

Color

|

Customized

|

|

Printing

|

Customized

|

|

Top

|

Full open/Filling spout/Top skirt/Duffle

|

|

Bottom

|

Flat/plain/with discharge spout

|

|

Liner

|

Liner(HDPE, LDPE) or Customized

|

|

Lifting loop

|

Cross-corner loops/4 Point 2 Strap lifting loop/Double Stevedore Strap/with belt/Fully belt loop/Loop in loop

|

|

Sewing

|

Plain/chain/chain lock with optional soft-proof

|

|

Ropes

|

1 or 2 around the bag body/customized

|

|

SWL

|

500-2000KG

|

|

SF

|

5:1/6:1/or as customer's requirement

|

|

Treatment

|

UV treated or not UV treated

|

|

Surface Dealing

|

Coated or plain,printing or no printing

|

|

Usage

|

Storage and packing

Mine,ore,fertilizer,chemical,onion,potato,grain,wheat,maize,rice,peanut,sugar,salt,agriculture,building material,powder,cement,etc. |

|

Processing

|

Yarn drawing-Circular weaving/Webbing-Quality inspection-Coating-Film

blowing-Cutting-Printing-Sewing-Checkout-Packaging-Transportation |

|

Delivery time

|

15-30 days

|

|

Certification

|

ISO22000, ISO9001, ISO14001, LABORDATA, etc.

|

|

Remark

|

Please let us know your specific requirements

|