In the complex world of packaging and logistics, the most critical components are often the ones you don't see. While a sturdy box or a vibrant outer bag catches the customer's eye, it's the humble PE inner bag working tirelessly behind the scenes. This unsung hero is the first and most important line of defense against a host of threats that can compromise product quality.

But what exactly is a PE inner bag, and why is it so indispensable across countless industries? Let's pull back the curtain on this essential packaging solution.

(H2) What is a PE Inner Bag?

A PE (Polyethylene) inner bag is a flexible bag made from polyethylene plastic, designed to be placed inside outer packaging like cardboard boxes, drums, or woven polypropylene bags (often called PP bags). They are also commonly known as liner bags or poly liners.

Their primary role is to create a protective barrier between the product and its external environment. Made from one of the most versatile and widely used plastics, PE inner bags are valued for their durability, flexibility, and excellent protective properties.

(H2) Key Benefits: More Than Just a Simple Bag

Why should you consider using a PE inner bag? The advantages are clear and impactful:

Superior Moisture Barrier: This is their flagship feature. PE plastic is inherently resistant to water vapor, creating an effective shield against humidity, condensation, and liquid spills. This is absolutely critical for keeping products like food, chemicals, or pharmaceuticals dry and stable.

Contamination Control: Inner bags seal out dust, dirt, and other airborne contaminants. This ensures your products arrive in pristine, clean condition, protecting both their quality and your brand's reputation.

Product Containment: For fine powders or granular materials (like flour, spices, or certain chemicals), PE liners prevent leakage and "sifting" through the seams of outer packaging. This keeps your storage areas clean and prevents product loss.

Cost-Efficiency: PE inner bags are an incredibly economical way to enhance your packaging. They allow you to use less expensive outer packaging (like corrugated boxes) multiple times, as the inner bag takes the brunt of the wear and tear from the product itself. They also reduce waste from spoiled goods.

Versatility & Customization: Available in a vast range of sizes, thicknesses (gauge), and styles—including flat bags, gusseted bags (for larger volumes), and bags with zip seals or tack seals. They can also be custom-printed with branding, handling instructions, or logos.

(H2) Where Are PE Inner Bags Used? Applications Across Industries

The versatility of PE inner bags makes them a go-to solution for numerous sectors:

Food & Beverage: Protecting dry goods like grains, nuts, coffee, and powdered ingredients from moisture and rancidity. They are often made from food-grade PE.

Pharmaceuticals & Healthcare: Safeguarding sensitive medical components, raw materials, and drugs from contamination and moisture to ensure efficacy and safety.

Chemicals & Agriculture: Containing fertilizers, pesticides, pigments, and industrial powders safely, preventing caking and preserving their chemical properties.

E-commerce & Retail: Acting as a protective liner inside shipping boxes for clothing, textiles, and non-food items, shielding them from potential water damage during transit.

Manufacturing: Storing and protecting parts, components, and raw materials from dust and corrosion on the factory floor.

(H2) Choosing the Right PE Inner Bag: A Quick Guide

Not all liners are created equal. Consider these factors for the perfect fit:

Thickness (Gauge): Thicker bags offer more puncture resistance for heavier or sharper products.

Size: Must be appropriately sized to fit snugly inside your outer container without excessive overhang.

Seal Type: Choose from heat seals for a permanent closure, zip seals for resealability, or tack seals for easy opening.

Material Grade: Ensure food-grade or FDA-compliant materials for consumable products.

(H2) A Small Investment for Significant Protection

In the grand scheme of your packaging budget, PE inner bags represent a minimal cost for maximum payoff. They are a simple, smart, and highly effective strategy to reduce loss, enhance customer satisfaction, and protect your bottom line.

(H1) Upgrade Your Packaging Strategy Today

Don't leave your products vulnerable. By integrating high-quality PE inner bags into your packaging process, you invest in peace of mind, ensuring your products are delivered in perfect condition, every time.

Ready to find the perfect protective solution for your products? Explore our range of customizable, high-performance PE inner bags and discover how a small change can make a huge difference.

|

Description

|

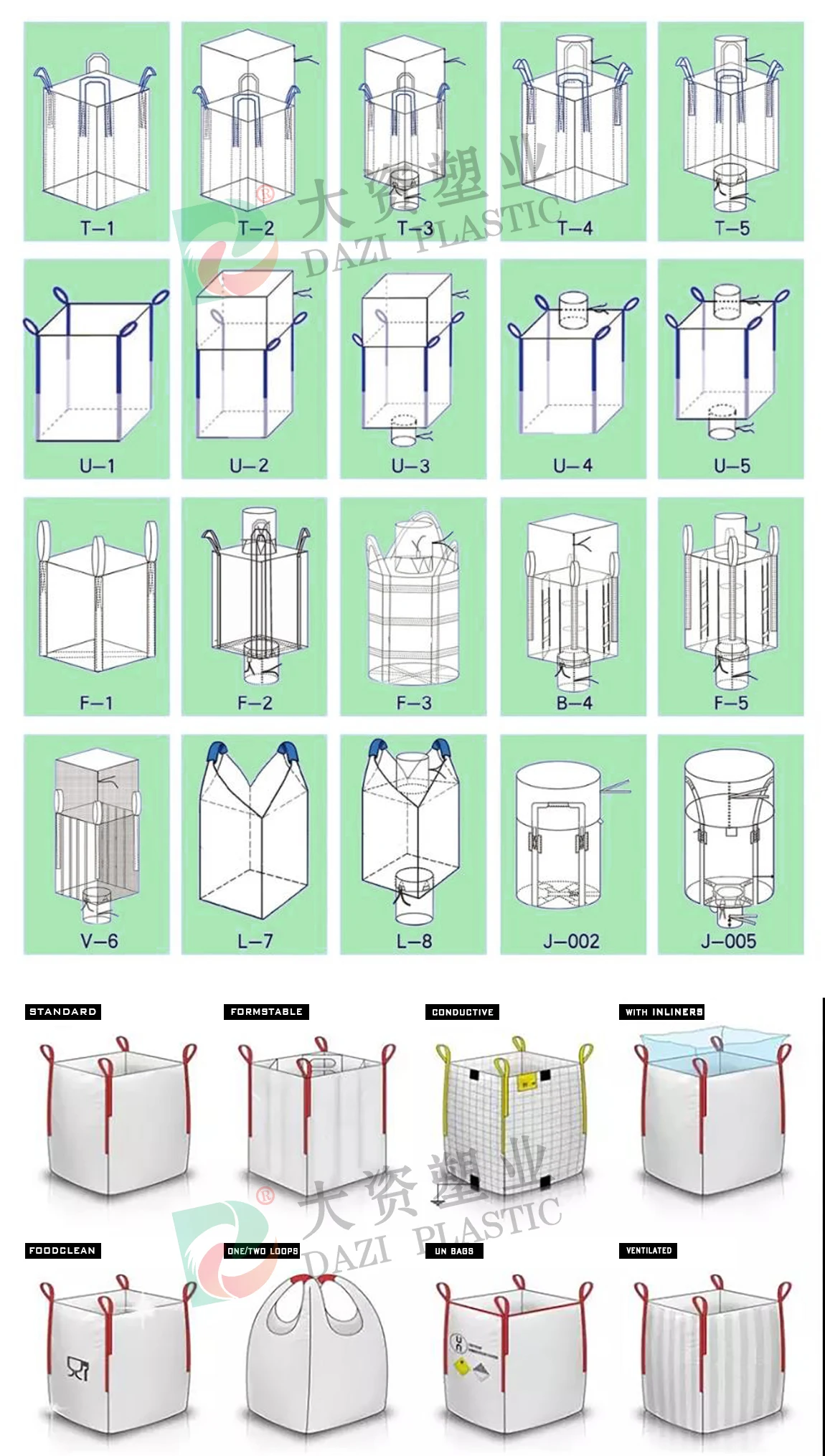

FIBC/Jumbo bag/bulk bag/ pp big bag/Flexible container bag professional manufacturer

|

|

Type of bag

|

Tubular/Circular/U-panel shape//Rectangular

|

|

Material

|

100% Virgin PP

|

|

Fabric

|

Laminated/Plain/Vent/Conductive

|

|

Size

|

Customized

|

|

GSM

|

110gsm-230gsm

|

|

Color

|

Customized

|

|

Printing

|

Customized

|

|

Top

|

Full open/Filling spout/Top skirt/Duffle

|

|

Bottom

|

Flat/plain/with discharge spout

|

|

Liner

|

Liner(HDPE, LDPE) or Customized

|

|

Lifting loop

|

Cross-corner loops/4 Point 2 Strap lifting loop/Double Stevedore Strap/with belt/Fully belt loop/Loop in loop

|

|

Sewing

|

Plain/chain/chain lock with optional soft-proof

|

|

Ropes

|

1 or 2 around the bag body/customized

|

|

SWL

|

500-2000KG

|

|

SF

|

5:1/6:1/or as customer's requirement

|

|

Treatment

|

UV treated or not UV treated

|

|

Surface Dealing

|

Coated or plain,printing or no printing

|

|

Usage

|

Storage and packing

Mine,ore,fertilizer,chemical,onion,potato,grain,wheat,maize,rice,peanut,sugar,salt,agriculture,building material,powder,cement,etc. |

|

Processing

|

Yarn drawing-Circular weaving/Webbing-Quality inspection-Coating-Film

blowing-Cutting-Printing-Sewing-Checkout-Packaging-Transportation |

|

Delivery time

|

15-30 days

|

|

Certification

|

ISO22000, ISO9001, ISO14001, LABORDATA, etc.

|

|

Remark

|

Please let us know your specific requirements

|